Search projects

Filter projects by markets or services

Client name: Wafi-Golpu JV

Location: Papua New Guinea

Duration: November 2016 – May 2018

Key features:

- 102 km of buried DN700 HDPE lined steel pipeline

- 4.8 MW of installed VSD driven tailings disposal pumping capacity

- Impressed current cathodic corrosion protection system

- Pipeline leak detection system

- Pipeline choke station to prevent pipeline slack flow

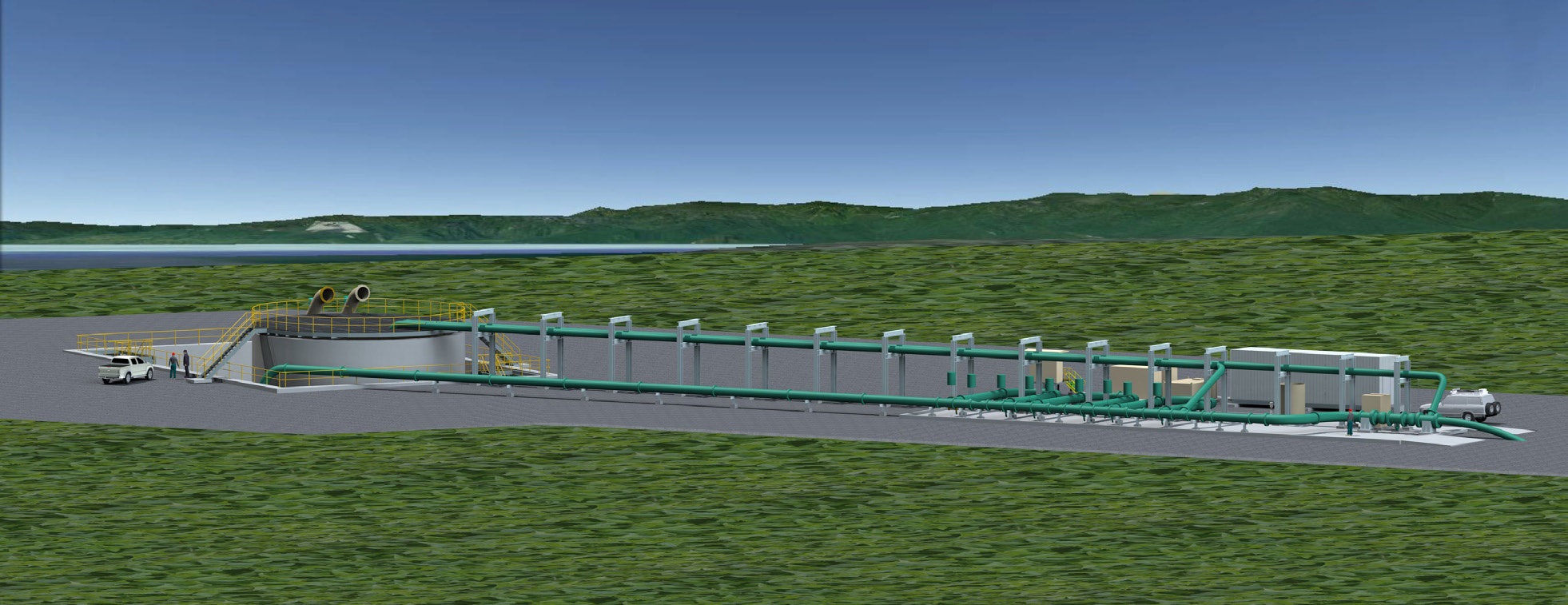

- 17m deep tailings mix tank located within a 12m deep dry moat

- Dual subsea 350m long 10000 OD HDPE seawater intake pipelines

- Dual subsea 930m long 800 OD HDPE ocean outfall pipelines

Wafi-Golpu Deep Sea Tailings Placement Feasibility Study

The Wafi-Golpu mine’s deep sea tailings placement system consists of a single 102KM DN700 HDPE lined steel pipeline fed by three 1.6MW positive displacement piston diaphragm pumps delivering tailings to pipeline choke station which discharges to a near shore below ground mixing tank.

The mixing tank received sea water under gravity from dual subsea seawater intake pipelines, where it mixes with the tailings before being discharged under gravity through dual subsea ocean outfall pipelines. The design throughput of the system is 2,050 tph.

Tetra Tech Proteus undertook the terrestrial portion of the preliminary design while Tetra Tech EBA completed the marine portion of the preliminary design. All aspects of the design were considered including earthworks and civil, concrete, structural, mechanical, piping, electrical, instrumentation and control.

Sorry, the comment form is closed at this time.